Recognizing the Relevance of Timely Stretch Wrap Device Repair Solutions

When it comes to stretch cover makers, timely repairs can make all the difference. You recognize that even small mechanical or electric issues can bring about unforeseen downtime, impacting your assembly line. Dealing with these troubles swiftly not only maintains effectiveness yet likewise boosts the high quality of your wrapped products. So, what factors should you take into consideration to guarantee your makers stay in top form? Allow's explore this essential aspect even more.

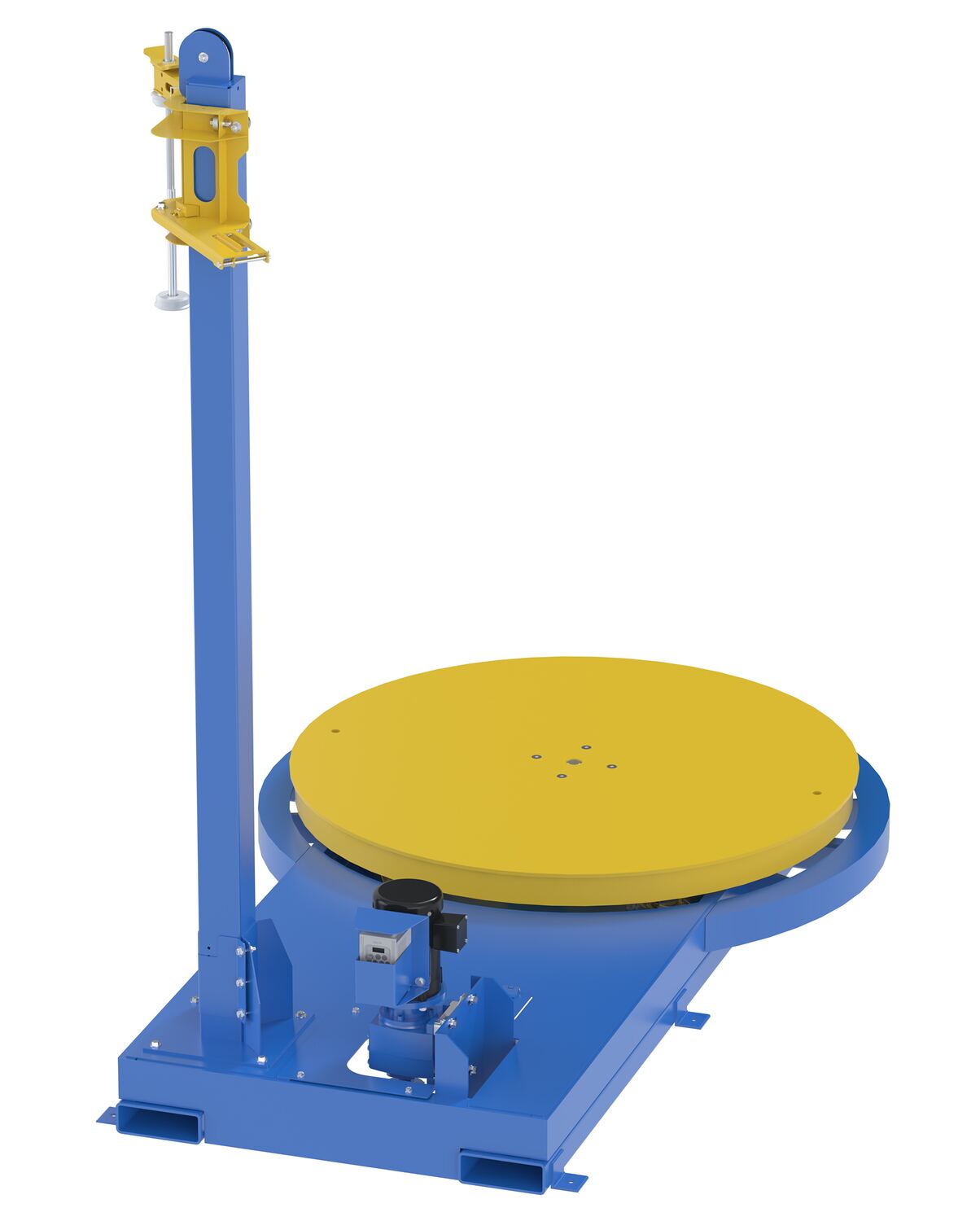

The Function of Stretch Wrap Machines in Modern Production

Stretch cover equipments play an essential function in contemporary production by making certain that products are securely packaged for transport and storage. You rely upon these makers to give security and protection, avoiding damage during transit. When you use stretch wrap, you reduce the threat of things changing or obtaining smashed, which can bring about pricey losses.

In addition, utilizing stretch cover devices can boost your overall supply chain effectiveness. By simplifying the packaging process, you lower labor costs and accelerate distribution times, ensuring that your customers get their items quickly. In today's busy market, this benefit is vital.

Common Problems That Cause Equipment Downtime

When your stretch cover machine experiences downtime, it can typically be mapped back to mechanical failings or driver mistakes. Recognizing these common issues can help you avoid expensive disruptions. By attending to these factors, you can keep your operations running smoothly.

Mechanical Failures and Break Downs

Mechanical failings and malfunctions can considerably interrupt your operations, causing expensive downtime. These problems typically come from worn-out components, such as gears and belts, or not enough lubrication. When components put on down or break, your stretch cover equipment might stop suddenly, affecting efficiency. In addition, electric failings can create breakdowns in the device's control system, producing further hold-ups. Normal maintenance is vital to capture these issues early and keep your equipment running efficiently - stretch wrap machine repair. Neglecting minor issues can bring about bigger, much more expensive fixings down the line. By focusing on timely fixings, you're not only minimizing downtime however also expanding the life expectancy of your machine. Keep proactive, and maintain your operations reliable and undisturbed.

Driver Mistakes and Oversights

While drivers play a crucial role in the smooth functioning of your stretch wrap machine, their errors and oversights can lead to substantial downtime. Common issues like inappropriate loading, incorrect settings, and failing to check wrap tension can cause hold-ups and item damage. Ultimately, investing in driver training pays off by boosting efficiency and prolonging your maker's life expectancy.

The Financial Effect of Postponed Repairs

Postponing repair work on your stretch wrap equipment can lead to considerable financial effects that surge with your whole procedure. When your machine breaks down, performance plummets.

Furthermore, prolonged hold-ups can escalate small issues right into major problems, needing more considerable repair services and even total replacement of the device. This can strain your budget click this site and interrupt money flow. Hold-ups can also impact your delivery schedules, hurting customer fulfillment and potentially creating you to lose service to competitors. Eventually, prompt fixings are vital to preserving your profits and guaranteeing smooth procedures. Don't undervalue the economic effect of ignoring those repair needs.

Advantages of Proactive Upkeep Programs

Timely repair services can save you from costly downtime, but implementing an aggressive upkeep program takes it an action further. By regularly arranging maintenance, you can determine possible issues prior to they rise into major troubles. This not just maintains your stretch cover equipment running smoothly but also expands its life-span. You'll find that regular maintenance decreases the likelihood of unexpected malfunctions, permitting your procedures to run much more efficiently.

Furthermore, a proactive strategy improves productivity. With less interruptions, your labor force can concentrate on their jobs without the stress of unexpected machine failings. And also, you'll likely conserve on repair work costs, as minor problems are generally less costly to repair than considerable repairs. Ultimately, preserving peak efficiency can improve the top quality of your covered products, making sure consumer satisfaction. In the lengthy run, a positive upkeep program is a financial investment that repays via boosted reliability and cost savings.

Determining Indications That Your Maker Needs Repair

As you operate your stretch wrap equipment, it is crucial to remain cautious for indicators that show it may need repair. If the movie isn't stuck appropriately or you discover uneven stress, your equipment could be malfunctioning.

If your maker frequently stops or calls for modifications, it is time to investigate. Maintain an eye on the device's rate; if it's slower than normal, something might be incorrect.

Selecting the Right Fixing Service for Your Requirements

How do you choose the appropriate repair service for your stretch cover maker? Look for technicians who specialize in stretch wrap devices and have a tested track document.

Next, assess their action time. A reputable additional hints solution needs to supply punctual assistance, as machine downtime can be costly. It's also important to understand if they offer emergency repair services.

Don't fail to remember to inquire about service warranties on fixings and components. A reliable service supports their work, giving you peace of mind.

Lastly, compare pricing but avoid selecting exclusively based upon price. Occasionally, the cheapest option may lead to subpar service. By considering these aspects, you'll locate a fixing solution that fulfills your demands and maintains your stretch wrap equipment running efficiently.

Methods for Lessening Stretch Cover Maker Downtime

Training your drivers is an additional vital method. Outfit them with the knowledge to determine and resolve small glitches before check my reference they cause substantial break downs. Motivate them to maintain a log of any irregularities, which assists in detecting issues quicker.

Furthermore, keeping an inventory of important spare parts can drastically decrease downtime. When something breaks, having the ideal components handy suggests you will not need to await deliveries.

Last but not least, consider buying real-time monitoring systems. These systems can notify you to performance changes, allowing for immediate intervention. By implementing these techniques, you'll keep your stretch wrap device running smoothly and efficiently.

Frequently Asked Inquiries

Just How Usually Should Stretch Cover Machines Be Serviced?

You need to service stretch cover equipments regularly, ideally every 6 months. If you see any type of performance issues or uncommon noises, don't wait-- timetable maintenance instantly to prevent pricey breakdowns and assure peak effectiveness.

What Are the Common Prices Linked With Stretch Wrap Equipment Services?

Common costs for stretch cover device fixings differ, but you could expect to spend in between $200 to $1,500 depending upon the issue. Normal maintenance can aid lessen these expenses and expand your maker's lifespan.

Can I Perform Standard Upkeep on My Stretch Wrap Equipment?

Yes, you can execute fundamental upkeep on your stretch cover machine. Regularly inspect for wear and tear, cleanse the components, and assurance proper lubrication. Maintaining it in great shape can prolong its lifespan and enhance efficiency.

Exactly how Do I Know if a Repair Solution Is Trusted?

To locate a reliable repair work solution, examine on the internet evaluations, request recommendations, and confirm certifications. A reputable service will give clear price quotes, warranty options, and punctual interaction, ensuring you feel certain in their competence.

What Should I Carry out in Instance of an Emergency Device Malfunction?

In instance of an emergency situation machine break down, you ought to promptly quit procedures, assess the issue, and contact your repair service. Keep vital get in touch with numbers helpful, and record the trouble for reliable repairing when aid gets here.

Verdict

To sum up, comprehending the significance of prompt stretch cover device fixings can considerably improve your procedures. Keep in mind to stay cautious for indications of wear and choose a trusted repair work solution to keep your equipments running smoothly.

Comments on “Don’t wait until equipment failure to schedule essential stretch wrap machine repair services.”